Applications

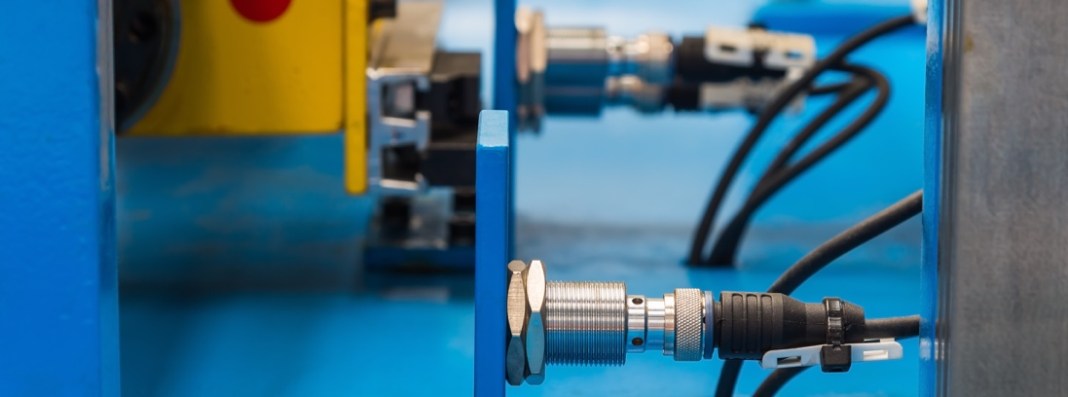

In general, inductive proximity sensors are used any time you want to detect the presence of a metal in a particular location. The most common application for inductive proximity sensors is machine position verification. Another application would include detecting the presence of a part in a manufacturing process. This could include a bolt, nut, metal panel or any other ferrous item that is present in a larger device. Alternatively, these sensors could also be used to positively identify the lack of metal in a manufactured item, such as a portion of the metal that has been punched, stamped or machined out. A third potential application would be part position verification. In this scenario, the inductive proximity sensor would be used to verify that a metal subcomponent is in place before a particular assembly process begins. A common example of this would include an automated welding process.

Advantages:

- Capable of withstanding harsh environments including industrial applications and washdown

- Generally easy to install and maintain

- Able to withstand a high number of cycles for a longer lifespan

- High switching rates to support faster cycle times

Limitations:

- Unable to detect objects that are not metallic

- When detecting non-ferrous materials (aluminum, copper, etc), range may be affected unless using a Universal or Factor 1 sensor type

- Generally has a limited sensing range of 60 mm or less

- Can only detect the presence of an object, but not the shape, color or orientation